ECM is a historical actor in the induction sector. In the early The 90s, ECM and CFEI (previously Saphymo Cell) – both members of the Dynathermic

group – proposed heat treatment installations, under vacuum and under

controlled atmosphere. During these years, ECM Technologies also proposed

revolutionary low pressure carburizing solutions for induction heating: the

TORR machine.

ECM’s mastery of high temperatures, vacuum, and controlled

atmospheres has allowed ECM TECHNOLOGIES to propose turnkey induction solutions

for various applications. Induction furnaces offer the possibility to carry out

complex processes at high temperatures (up to 3000°C), with a rapid rise in

temperature (30°C/s).

These induction melting solutions are now dedicated to the

elaboration of materials and more especially, to materials with strong added

value. Also, ECM’s installations allow the melting of materials in an ATEX,

corrosive or nuclear environment.

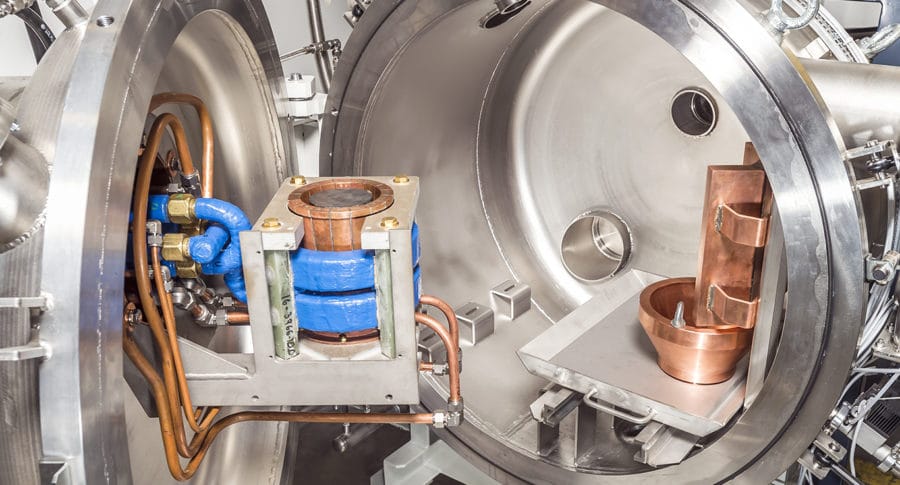

The elaboration and fusion of high added value materials or

the improvement of the materials’ physical properties all take place in a vacuum

or controlled atmosphere furnaces. The technologies used can be a cold crucible

for reactive materials (crucible with cooled copper or stainless steel parts),

a hot crucible (graphite or other) or a susceptor or muffle radiating on the

heated material.

Therefore, cold electric insulating materials (ceramic,

glass, enamel, silicon) can be treated in ECM’s induction furnaces. Plasma

solutions can be considered as a means to purify materials. ECM Technologies’

melting solutions such as VIM (Vacuum Induction Melting installations), CCIM

(Cold Crucible Induction Melting installations) or any other melting furnace

uses the latest technologies to propose the best solution to its customers.

Also, all these technologies open to a wide range of applications and can be

adapted to each customer’s need with the capacity to offer tailor-made

solutions.

No comments:

Post a Comment